的主要用途是什么与介简/Purpose and introduction:

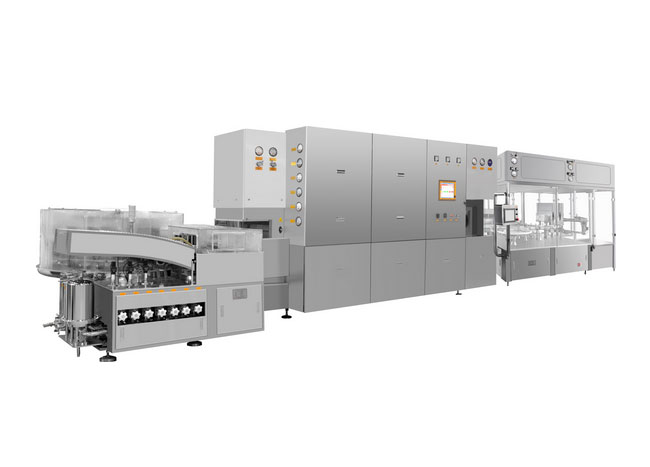

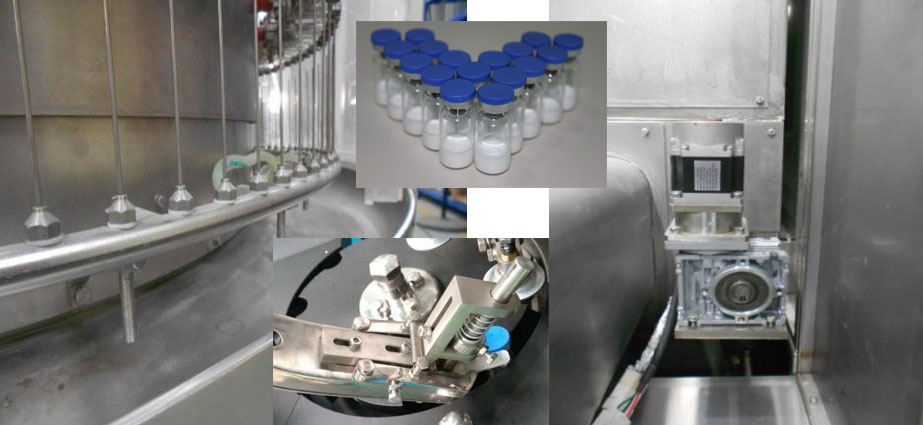

NQGF型西林瓶粉针洗烘灌装轧盖标贴纸联调线 由QCL产品系列的立柱式彩超波洗瓶机、AQMR隧洞式自动空调无限循环系统过滤除菌烘烤箱、NQFGX产品系列的车床挤出机螺杆粉剂灌装机、NQ-50轧盖机、NQWTB-120标贴纸空气能机组成,也可pc单机便用。合适于7-25ml型号规格的西林瓶粉针的产出。能完整自动喷淋系统加压、彩超波粗洗、瓶侧壁水情况呢、瓶开口处间隔首次无限循环系统水情况呢、次吹气、次鲜美水情况呢、间隔首次吹气、瓶侧壁吹气、洗涤、点火、烘干阶段过滤除菌去热原、冷却水、灌装、加塞、轧盖、标贴纸等二十来道工艺流程。NLGF schering bottles booster injection wash baked repackaging rolling cover labeling line consists of QCL series vertical ultrasonic bottle washer, ASMR tunnel type hot air circulation oven. NFFGX series CNC screw powder filling machine, NF-50 rolling machine, NFWTB-120 labeling machine, and also can be used stand-alone. Suitable for 7 to 25 ml specification schering bottles of water production. Can finish the spray water injection, ultrasonic thick bottle washing, the outer wall of water flushing, bottle wall continuous secondary circulating water flushing, a blowing, a fresh water rinse, two consecutive bottle blowing, blowing the outer wall, preheating and drying sterilization to pyrogen, cooling, packaging, gasser, cover, labeling and so on more than 20 procedures.

优缺点/characteristic:

◆洗瓶机主要采用机械装备手夹瓶,不适用几种规模的西林瓶;Bottle washer adopts manipulator clamp bottle, is suitable for a variety of specifications of schering bottles;◆洗瓶使用水蒸气喷针循环往复跟进放入的方法,洁净的效果非常好,不浪费的行为能源资源。并设在针架防晃动装制,升高喷针放入玻璃瓶的合理度,少断针症状造成;Reciprocating mixer washing bottle with water spray needle track insert way, cleaning effect is good, save energy. And is equipped with needle shake device, improve the accuracy of injection needle inserted into the bottle, reduce breakage phenomenon;◆洗瓶一整块气水管线、喷针几乎独立自主分离开来,不要了平行环境污染,符合标准GMP规范化条件;Mixer washing bottle the water pipe, injection needles completely separate, to avoid the cross contamination, in line with the GMP requirements;◆洗瓶机进瓶挤出机螺杆式前可以加装部件实现降低块,有维护挤出机螺杆式,才能减少碎瓶帮助;Pieces into the bottle inside the screw before adding buffer block, protect the screw, reduce broken bottle;◆洗瓶机出瓶使用整体布局进出口同部带,进行连接拨瓶块气力输送机西林瓶,自动运行不稳稳定可靠;Pieces out of the bottle inside the whole import synchronous belt, the connection dial the bottle conveying schering bottles, operation is stable and reliable;◆烘干箱应用热气循环法高温,摄氏度饱满,节约;Oven adopts hot air circulation heating, temperature uniformity, energy saving;◆烤箱应设防突发关闭电源保护区模块。开机运行健康安全;Mixer oven has suddenly loses power protection function. Run security;◆恒温干燥箱可配再循环水冷散热部件,不消耗的资金卧室功率,减轻卧室的压力不静态平衡的问题制冷的好用吗;Mixer oven can match circulating water cooling device, not loss room air volume, reduce the risk of differential pressure imbalance in room cooling effect is good.◆干燥箱可配差压自行和平调准整体减低房間和干燥箱的差压不和平导致的常温段位移,灌装设备间洗烘间工作温度升职业技术一产品系列的现象;Mixer automatic oven can match differential pressure balance control system to reduce the room and high temperature oven pressure difference caused by the imbalance of period of migration, filling between wash between baking temperature and so on a series of problems;◆烘干箱开设DOP检验主板接口(例如风压差、风力、颗粒离子检验口);Mixer oven with DOP test interface (including wind pressure, wind speed, dust particle detection);◆真空烘箱降温段可带迅雷在线灭菌方法作用(FDA特选);Mixer oven cooling segment with the function of sterilization (FDA selected);◆恒温干燥箱网带可带多普勒彩超蔓延到CIP在线平台除污系统性;Type mixer oven mesh belt with ultrasound scanning CIP online cleaning system;◆烘干箱内腔室可做全东南方向、多方面直流电水清洗阴道;In pieces inside the oven chamber can be all-round, multi-angle high-pressure water flushing;◆散装机使用国际上更先进集体的设计构思心理,具备有高访问速度度,所以分瓶合理,进行更换规格参数件不方便;Mixer racking machine adopts the most advanced design concept, high speed, and bottles of accurate, replacement of a convenient;◆散装机采用了学习交流伺服线束减速机驱程散装挤出机螺杆缩放,装量精准;Mixer racking machine adopts ac servo motor drive the repackaging screw rotation, the load accurately;◆散装机运用装量的调节简单在触模屏上实现了;Mixer packer adopts the load adjustment directly on a touch screen;◆分开包装机可以选择配百级巡环式层流罩;Mixer packer optional circulating laminar flow hood best level;◆包装机无瓶变慢包装,无瓶没加塞效果。Racking machine without stop packing bottle, no bottle no stoppered function.◆整线利用PLC总操纵、变频器、触碰屏操纵工艺,进行稳定性安全可靠的。触碰屏可表现各电脑单机的进行阶段,各操纵点的水流量、压力、风速、温等表现,各转换开关阶段和机械出现问题表现,机械出现问题自我认识的诊断和机械出现问题定量分析及避免技巧。使整体生產的过程提升自己化操纵,联线享有自我控制平横裝置,确认生產均匀安全可靠的。The whole line adopts PLC control, inverter, touch screen control technology, stable and reliable running. Touch screen can display the running state of each units, each control point of the water pressure, air pressure, air pressure, temperature, etc, according to the switch state and fault display, fault self-diagnosis and fault analysis and elimination method. Make the whole production process automation control, on-line has the automatic balancing device, ensure production equilibrium is reliable.按照其客人的需求,还可供加装:According to the needs of customers, but also available for selection:◆simens、斯耐德、西门子、台达等茶叶品牌的控制模式;Pieces of Siemens, schneider, mitsubishi, Taiwan brands such as control system;◆水、气气压、油温及超音波波难度、颗粒物塑料再生颗粒、风力在线播放检查、短信报警、备案、彩印系统;Pieces of water, gas pressure, water temperature and the intensity of ultrasonic, dust particles, wind speed on-line detection, alarm, record and print system;◆ORABS、CRABS、无茵防护隔离器系统化。ORABS, CRABS, aseptic isolator system.系统性能参数:/technical parameters

规格 model | 出产量力production capacity | 洗瓶合格达标率Washing bottle percent of pass | 洗瓶划痕率Washing bottle breakage | 杀菌摄氏度sterilizing temperature | 分开装袋偏差The repackaging of error | 加塞通过率率Gasser percent of pass | 自然空气层流干钻戒颜色Laminar air cleanliness | 真空环境抽速Vacuum pumping speed | 电阻量 capacitance | 电power supply | 总储电量Total transmission energy | 性能尺寸大小boundary dimension |

7-25ML新国标西林瓶 7-25ML GBvial | 300瓶pcs/分min ~600瓶pcs/分min | ≥99% | ≤0.1% | 300℃-350℃ | ≤±3%(0.1-10h) | ≥99% | 100级100c | 25m3/H(外配)100cbm/H ~50m3/H(外配)100cbm/H | 96kw~235.5kw | 380v,50HZ | 约 8200KG | 约 2000×1750×2370mm |

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

成都纳庆机械工程机械设备制造工程机械设备非常有限装修公司

成都纳庆机械工程机械设备制造工程机械设备非常有限装修公司

中文

中文  English

English